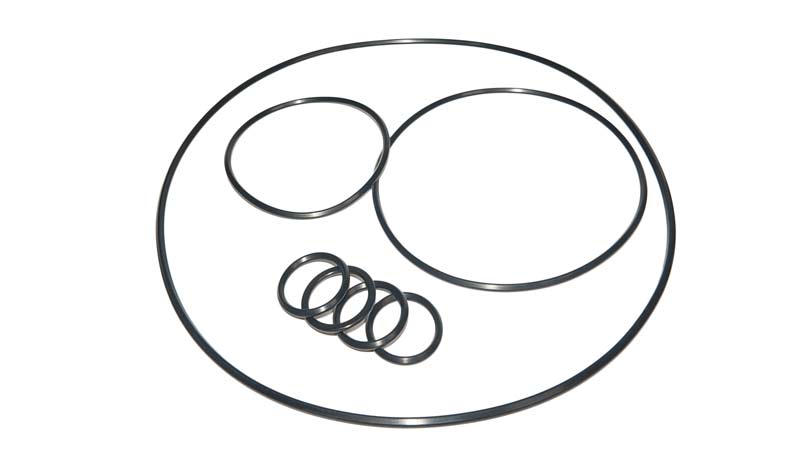

The inner spring is made with stainless steels such as F316, F304, F301 and with high alloys such as Elgiloy, Hastelloy C276, Inconel 718, etc. and may take the spiral or comb form.

This type of gasket is designed to operate at cryogenic temperatures at -270 ° C to very high temperatures that can exceed 300 ° C.

For the seal guarantee, based on valve application requirements such as operating pressure, temperature, fluids or gases of the flow, account is taken of the construction of the sheath and the spring.